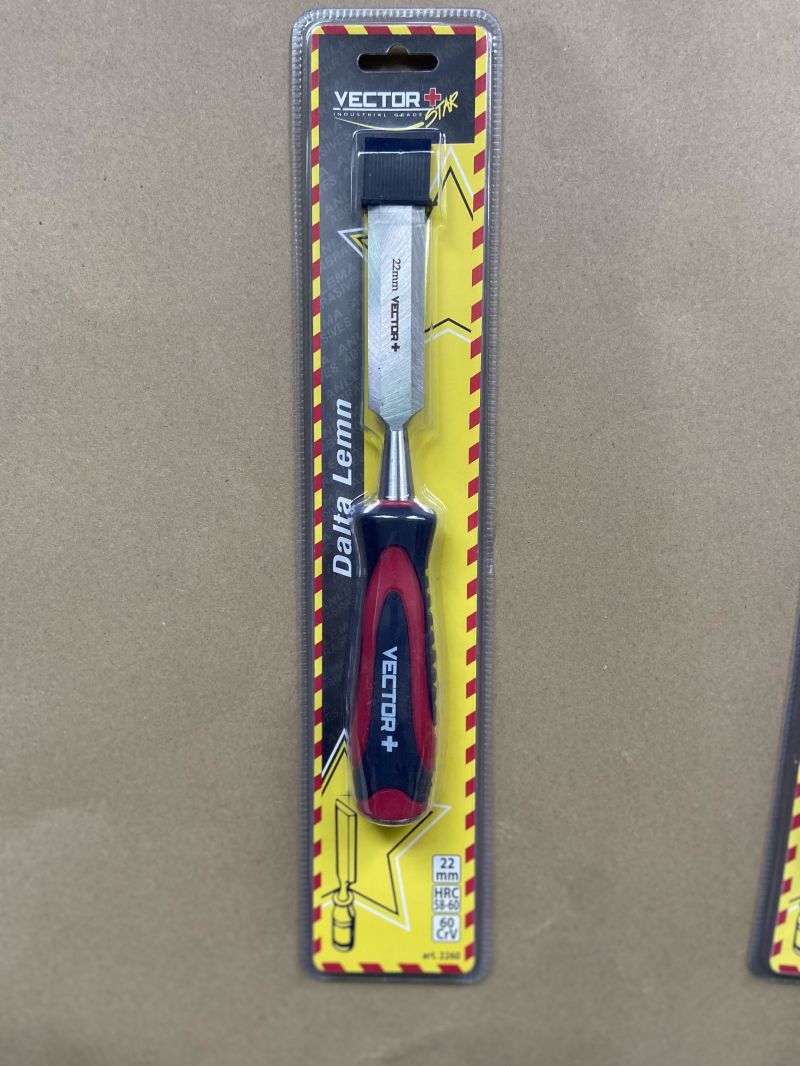

Lichesele tsa lehongke lisebelisoa tse sebelisetsoang ho rema, ho betla kapa ho rema lehong.Khetho e nepahetseng ea thepa le tsebo ea tšebeliso e ka ntlafatsa katleho le nako ea bophelo ea lichesele tsa lehong.Litlhahiso tse ling tsa khetho ea thepa ea lehong le litsebo tsa tšebeliso ke tsena:

Khetho ea thepa:

1. Tšepe e phahameng ea carbon: Tšepe e phahameng ea carbon ke ntho e tloaelehileng bakeng sa lichesele tsa lehong, tse fanang ka matla a matle le ho tšoarella.E loketse mefuta e mengata ea lehong, haholo-holo lifate tse thata le lifate tse phahameng haholo.

2. Tšepe ea lebelo le phahameng: Tšepe ea lebelo le phahameng ke thepa e nang le thata e babatsehang le botsitso ba mocheso.Hangata e sebelisoa bakeng sa ho tšoara lifate tse thata kapa maemo a hlokang ho rema ka lebelo le phahameng.

3.Motsoako oa tungsten: Tungsten alloy ke sesebelisoa se matla ka ho fetesisa le se sa senyeheng se sebelisoang ha ho etsoa lichesele tsa boleng bo holimo tsa patsi.E loketse ho sebetsa ka lehong le thata, plywood, le thepa e kopantsoeng.

Ho thatafalaea chisel ea lehong e itšetlehile ka thepa eo e entsoeng ka eona.Lichesele tsa lehong hangata li entsoe ka tšepe e phahameng ea carbon, tšepe e lebelo le holimo, kapa alloy ea tungsten, e nang le maemo a thata a fapaneng.Mona ke mefuta e batlang e le thata ea lisebelisoa tsena:

1. Tšepe e nang le carbon e phahameng: Tšepe e phahameng ea carbon e sebelisoang bakeng sa lichesele tsa lehong hangata e na le boima bo tlohang ho 55 ho ea ho 62 HRC (Rockwell Hardness Scale).Boemo bona ba boima bo lumella chisel ho boloka bohale bo bohale le ho hanela ho roala nakong ea tšebeliso.

2. Tšepe ea lebelo le phahameng: Tšepe ea lebelo le phahameng e sebelisetsoang lichesele tsa lehong e tsebahala ka ho thatafala ha eona ho ikhethang.Ka kakaretso e na le mefuta e thata ea 62 ho isa ho 67 HRC, e fana ka ho boloka moeli le ho hanyetsa mocheso le ho apara.

3. Tungsten alloy: Lichisele tsa alloy tsa Tungsten li thata haholo ebile lia tšoarella.Ka tloaelo li na le mefuta e thata ea 65 ho isa ho 70 HRC kapa ho feta.Boima bo phahameng ba tungsten alloy bo netefatsa ts'ebetso e ntle ea ho itšeha le bophelo bo atolositsoeng ba lisebelisoa.

Ho bohlokoa ho hlokomela hore boima bo nepahetseng ba chisel ea patsi bo ka fapana ho latela mofuta o itseng, ts'ebetso ea tlhahiso, le kalafo ea mocheso e sebelisoang sesebelisoa.Ka linako tsohle sheba lintlha tsa moetsi kapa u buisane le boitsebiso ba sehlahisoa ho fumana hore na ho thata hakae ha chesele e itseng ea lehong.

Tsebo ea ho sebelisa:

1. Boloka bohale: Ho ba bohale ho bohlokoa bakeng sa ho seha lichesele tsa lehong.Kamehla hlahloba lehare la chisel 'me u sebelise lejoe le hlabang kapa grinder ho boloka bohale.

2. Laola matla a ho itšeha: Ha u sebelisa lichesele tsa lehong, sebelisa matla a ho itšeha a itekanetseng 'me u qobe khatello e feteletseng.Matla a feteletseng a ka etsa hore chesele e khomarele kapa e senye lehare.Sebelisa mekhoa e bonolo ea ho sutumetsa le ho sotha ho ntšetsa pele lehare la chisel ka lehong.

3. Maemo a nepahetseng: Pele o qala ho cheka, tšoaea sebaka seo u se batlang u sebelisa rula, pentšele kapa sesebelisoa sa ho tšoaea.Etsa bonnete ba hore lehare la chisel le qala ho seha ho tloha sebakeng se nepahetseng bakeng sa liphetho tse nepahetseng.

4. Khetha sebopeho se loketseng sa lichesele: Lichesele tsa lehong li na le libopeho tse fapaneng, tse kang lichesele tse bataletseng, lichesele tse chitja le lichesele tse sekoere.Khetha sebopeho sa chisel se lumellanang le litlhoko tse khethehileng tsa mosebetsi bakeng sa liphetho tse nepahetseng.

5. Sebelisa mallet: Bakeng sa mesebetsi e hlokang matla a eketsehileng, u ka sebelisa mallet ea lehong ho thusa ho cheha.Tlanya ka bonolo mofeng oa chisel ho khanna lehare ka har'a patsi, empa ela hloko ho laola matla le ho qoba ho otla ho feteletseng ho ka bakang tšenyo.

6. Litlhokomelo tsa ts'ireletso: Kamehla u etelletse pele polokeho ha u sebelisa lichesele tsa lehong.Netefatsa hore patsi e tsitsitsoe ka mokhoa o sireletsehileng ho thibela ho thella kapa likotsi tse hlahang.Ho phaella moo, apara lisebelisoa tse loketseng tsa ho itšireletsa, tse kang tšireletso ea mahlo le liatlana, e le hore u itšireletse ha u ntse u sebetsa.

Nako ea poso: Phup-09-2023