Carbide Annular Cutter Ka Sesebelisoa sa Boleng ba Boleng bo Phahameng

RUIXIN Tool-HSS Annular Cutter

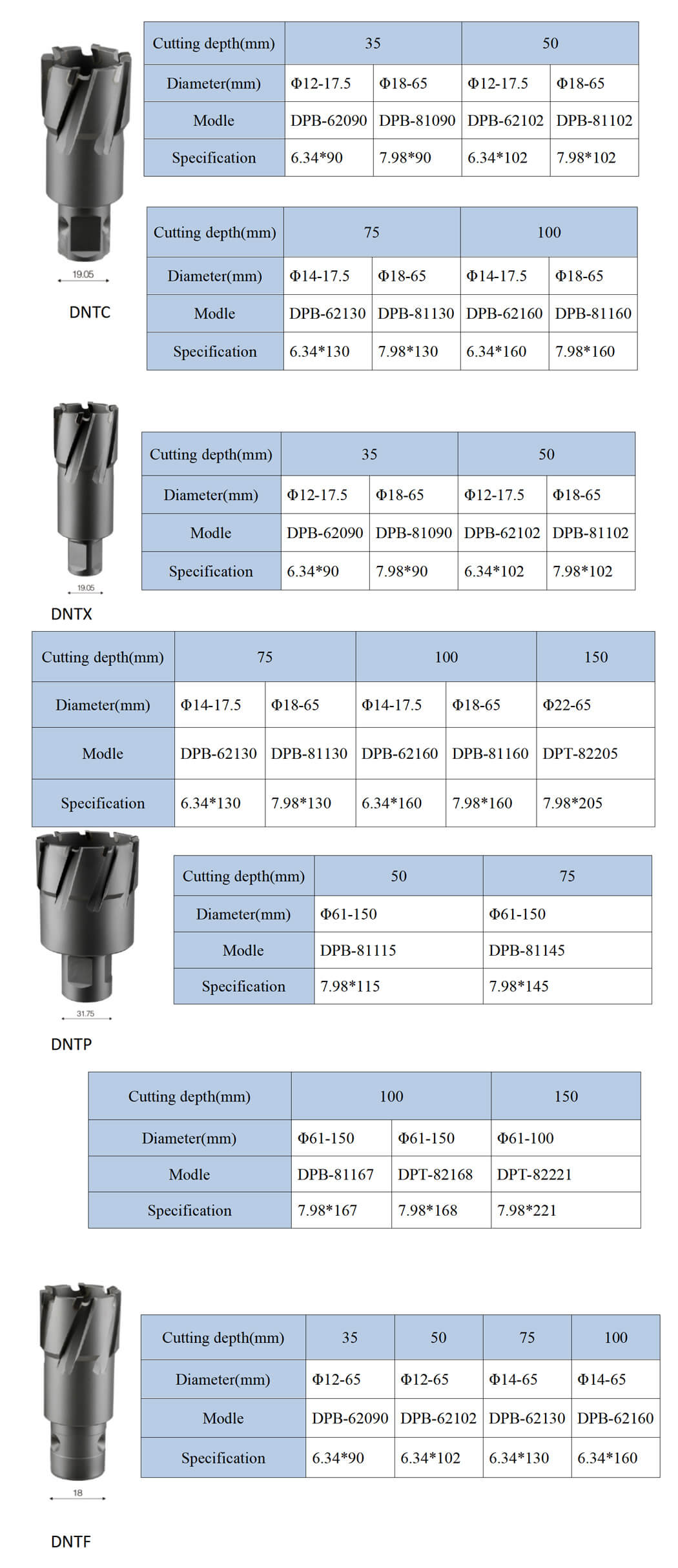

DNTC

DNTX

DNTP

DNTF

Tlhahisoleseding ya Sehlahiswa

Lebitso la Sehlahisoa:

1. Carbide annular cutter with universal shank (DNTC)

2. Carbide annular cutter with weldon shank (DNTX)

3. Carbide P-type annular cutter with weldon shank (DNTP)

4. Carbide annular cutter e nang le FEIN Quick-IN shank (DNTF)

Product Diameter: 12-150mm

Ho teba ha Sehlahisoa:35mm, 50mm, 75mm, 100mm, 150mm

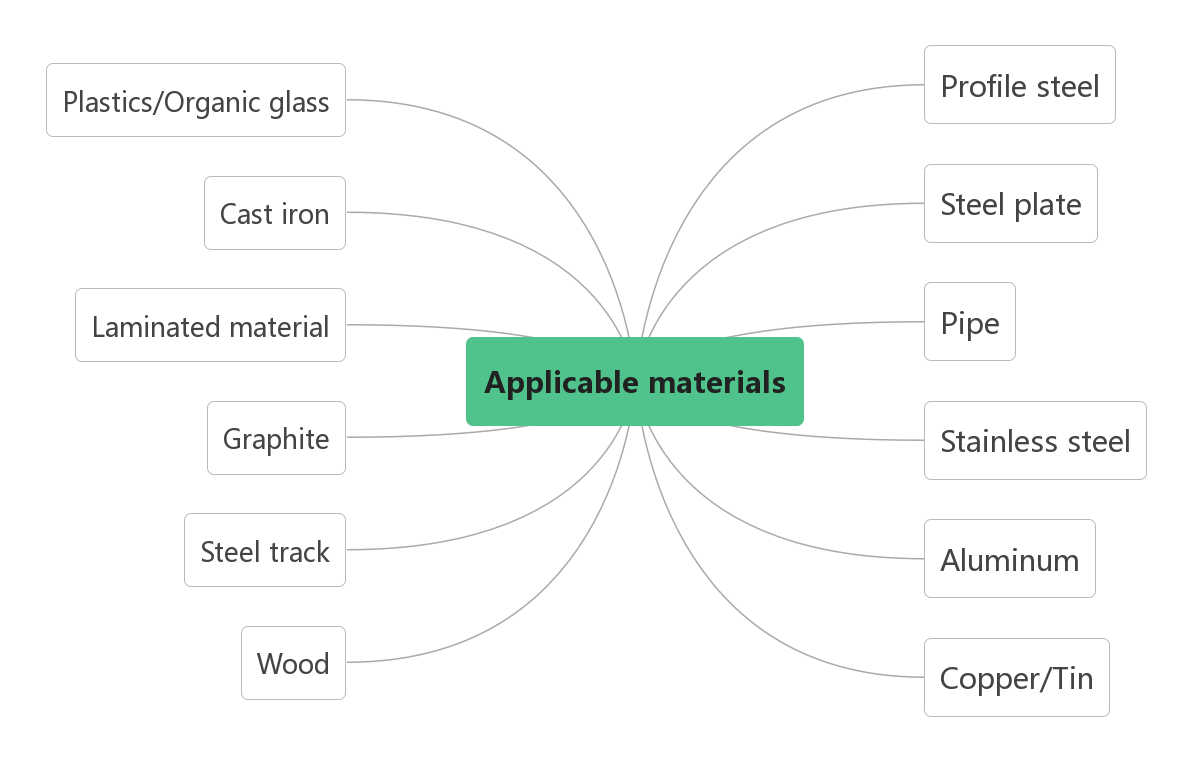

Lisebelisoa tsa Kopo ea Sehlahisoa:E loketse mefuta eohle ea tšepe ea mohaho, tšepe e kopantsoeng, tšepe e sa hloekang, aluminium, koporo, tšepe ea tšepe joalo-joalo.

Indasteri ea Kopo ea Sehlahisoa:Sebopeho sa tšepe, boenjiniere ba borokho, indasteri ea kaho ea likepe, mochini oa ho cheka oli, kaho ea terene, tlhahiso ea mochini, matla a motlakase le likarolo tse ling.

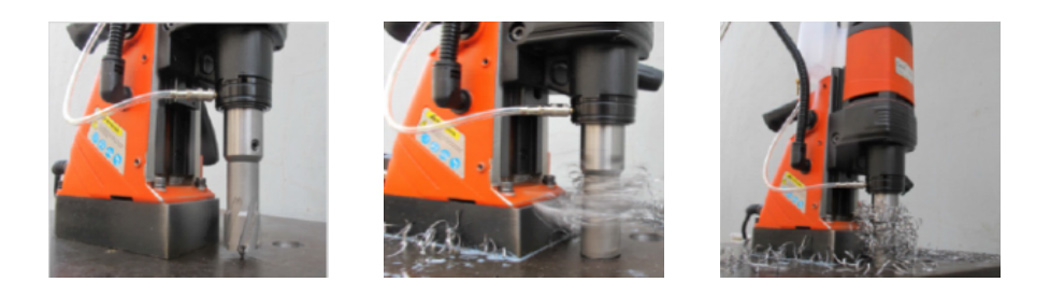

Hlahisa Sehlahisoa:Sehlahisoa sena ke lebelo le phahameng la ho phunya bakeng sa ho itšeha ka annular ka li-blades tse ngata.Ke sesebelisoa sa ho lokisa sekoti se loketseng lisebelisoa tse nkehang, empa ha se khone ho sebetsana le masoba a foufetseng.Haholo-holo e sebelisetsoa ho cheka likarolo tsa tšepe, ts'ebetso e bonolo le e bonolo, ka katleho e khutsufatsa nako ea kaho.

Mohlala le Tlhaloso

| Carbide annular cutter e nang le shank ea bokahohle | DNTC-3 | DNTC-4 | DNTC-5 | DNTC-6 |

| Diameter(mm) | Φ12-65 | Φ12-65 | Φ14-65 | Φ14-65 |

| Botebo ba ho itšeha(mm) | 35 | 50 | 75 | 100 |

| Carbide annular cutter e nang le weldon shank | DNTX-3 | DNTX-4 | DNTX-5 | DNTX-6 | DNTX-7 |

| Diameter(mm) | Φ12-65 | Φ12-65 | Φ14-65 | Φ14-65 | Φ22-65 |

| Botebo ba ho itšeha(mm) | 35 | 50 | 75 | 100 | 150 |

| Carbide P-type annular cutter e nang le weldon shank | DNTP-4 | DNTP-5 | DNTP-6 | DNTP-7 |

| Diameter(mm) | Φ61-150 | Φ61-150 | Φ61-150 | Φ61-100 |

| Botebo ba ho itšeha(mm) | 50 | 75 | 100 | 150 |

| Carbide annular cutter e nang le shank ea FEIN Quick-IN | DNTF-3 | DNTF-4 | DNTF-5 | DNTF-6 |

| Diameter(mm) | Φ12-65 | Φ12-65 | Φ14-65 | Φ14-65 |

| Botebo ba ho itšeha(mm) | 35 | 50 | 75 | 100 |

Lisebelisoa tse Tšebelisoang

Melemo ea Pele ea Tlholisano

1. Ka mefuta eohle ea ho tšoara, e loketse lisebelisoa tsohle tsa ho cheka motheo oa makenete lefatšeng;Litlhaloso tse felletseng, bophara bo boholo ba letoto le tloaelehileng ke 150mm, botebo bo boholo ba ho itšeha ke 150mm, 'me bophara bo boholo ba letoto le ikhethileng ke 200mm Maximum cutting deep 200mm.

2. Ho amohela mekhoa e lumellanang ea tšehetso ea tekheniki (peipi e chitja le ho itšeha ka laminated) ho latela litlhoko tse fapaneng tsa ts'ebetso.

3. Amohela lisebelisoa tsa matrix ka matla a babatsehang le ho tiea le mokhoa o khethehileng oa phekolo ea mocheso.

4. Amohela moralo oa moralo oa li-grooves tse telele le tse khutšoanyane ho ea ka botebo bo fapaneng ba ho cheka;Butle-butle ho bula sebopeho sa spiral groove, ho tlosoa ha chip e boreleli le ho cheka ho tsitsitseng.

5. Ts'ebetso ea lisebelisoa tsa mochini oa CNC ka ho feletseng, e nang le boleng bo tsitsitseng le bo tsitsitseng.

6. Lehare la carbide le entsoeng ka holimo le nang le ts'ebetso e phahameng le likaroloana tsa ultra-fine li amoheloa ho netefatsa bophelo ba tšebeletso.

Sets'oants'o sa Ts'ebetso setšeng

Litaba Tse Hlokang Tlhokomelo Bakeng sa Ts'ebetso e Sireletsehileng

1. Ka kopo, apara liaparo tsa mosebetsi le likhalase tse sireletsang bakeng sa ts'ebetso ho thibela litšepe hore li se ke tsa phatloha le ho senya letlalo le mahlo.

2. Sebetsa ha sehlahisoa se kenngoa ka nepo ho thibela kotsi.

3. Ha o kenya le ho tlosa sehlahisoa sena, ka kopo, ntša polaka ea motlakase kapa u hakolle phepelo ea motlakase.

4. Mocheso o hlahisoa nakong ea ho phunya ho qoba ho chesa le ho ama tikoloho e potolohileng.

5. U se ke ua fetola sehlahisoa sena ntle le tumello, ebe u etsa ts'ebetso ea ho phunya ho thibela lintho tse sa lebelloang hore li se ke tsa etsahala.

6. Nakong ea ho potoloha ha sehlahisoa, ho thibetsoe ka thata ho ama ka matsoho

7. Haeba ho na le ho thothomela, molumo o bohale le lintho tse ling tse sa tloaelehang nakong ea ts'ebetso, ka kopo emisa ts'ebetso, hlahloba sehlahisoa kapa u nkele sebaka se secha.

8. Ka kopo bala litaelo tsa ts'ebetso ea mochine le mochine pele u sebelisa sehlahisoa.