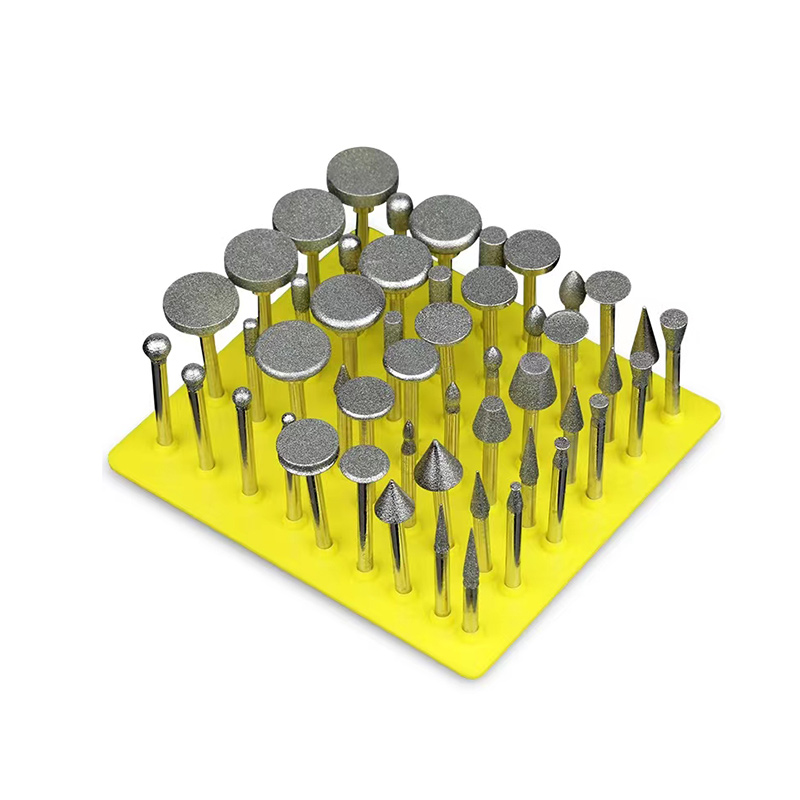

Emery Grinding Nale-Abrasive Tools

Boemo ba Modle

Selelekela sa Ntho

Lebitso la Ntho: Emery Grinding Nale

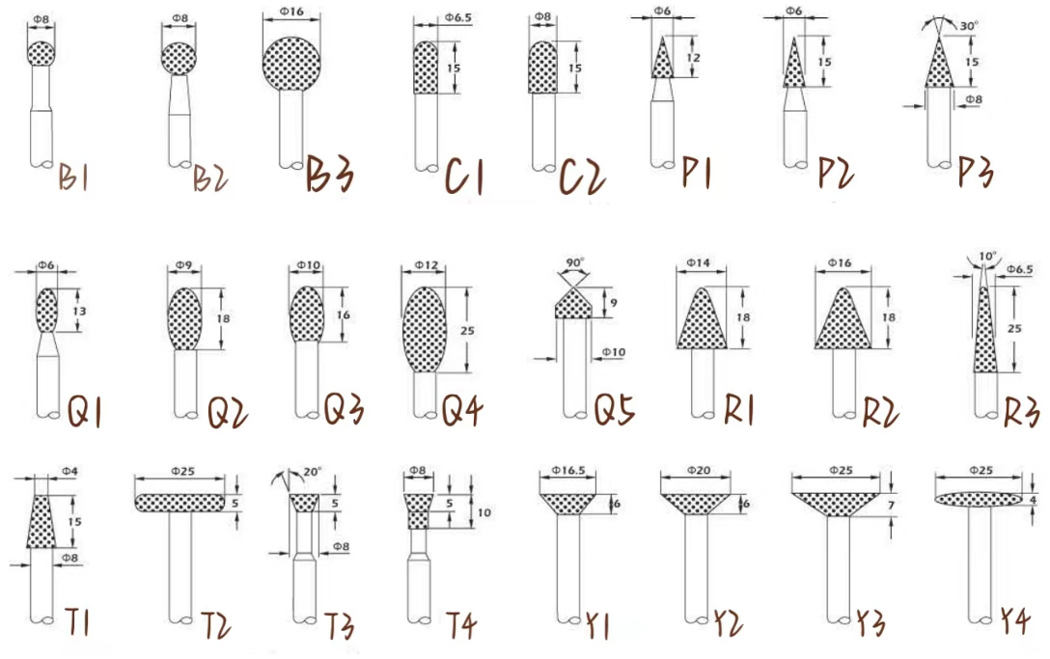

Ntho ea mohlala: B/C/P/Q/R/T/Y

Ntho ea Sehlooho sa Sehlooho: Diamond

Ntho e ngata: 50pcs / set

Kakaretso ea Bolelele: 45mm

Shank bophara: 3.2mm

ItemUsage: Haholo-holo e sebelisoa ka majoe, ceramics, khalase, carbide e entsoeng ka samente, lehakoe, ts'ebetso ea jade le masimo a mang.

Melemo: E entsoe ka daemane ea maiketsetso le electroplating ea taemane e matla haholo.Lehlabathe le tšoana ebile le tšoarella.

Kenyelletso ea Sehlahisoa: Sehlahisoa sena se sebelisa ho roala ha daemane, se sebelisoa haholo ho betla, ho sila, ho poma, ho sila hantle le ho sila ka lesoba le ka hare la lirafshoa, likhalase, mahakoe, li-alloys le lisebelisoa tse ling tse manganga.

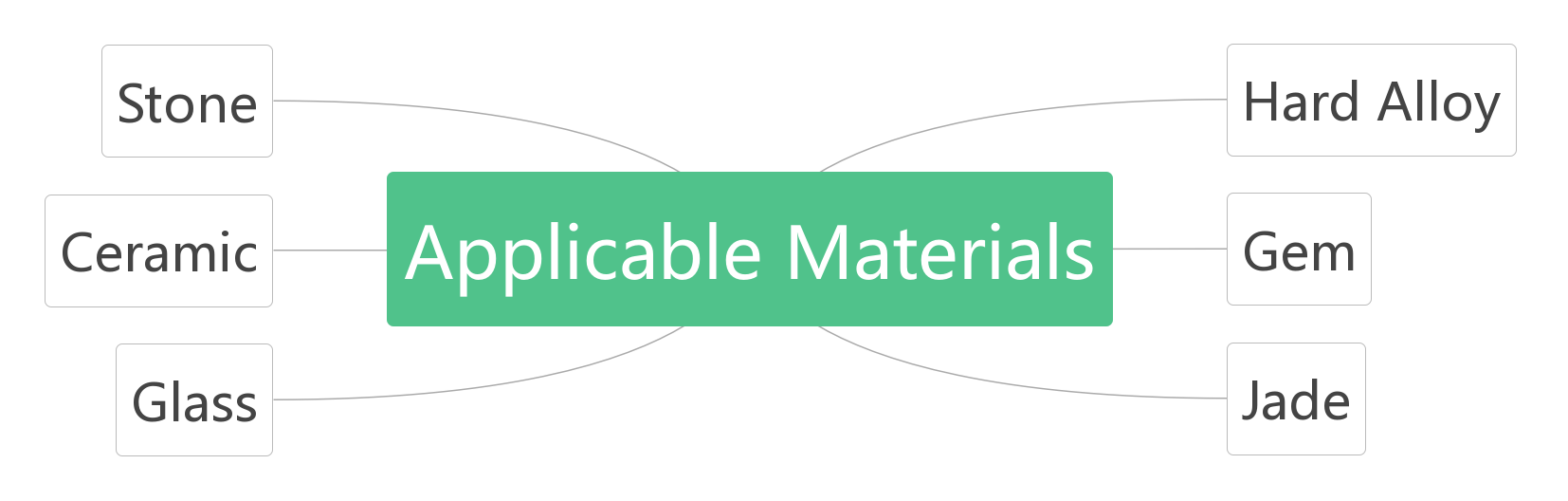

Lisebelisoa tse Tšebelisoang

Jade

Li-ceramics

Lejoe

Alloy e thata

Khalase

Lehakoe

Kopo

E sebelisoa haholo ho betla, ho sila, ho kuta, ho sila hantle le ho sila ka har'a sekoti se ka hare sa li-ceramics, likhalase, majoe a majoe, li-alloys le lisebelisoa tse ling tse sa senyeheng.E sebelisetsoa ho bentša le ho khaola bokaholimo ba ntho le ho sila sehahi.

Scenario e sebetsang

Molemo

1. Thepa ea boleng bo holimo, e sa sebetseng ebile e tšoarella, bophelo bo bolelele ba ts'ebeletso.

2. Fana ka mefuta e fapaneng ea litlhaloso, tse sebelisoang haholo.

3. Lihlahisoa tse bohale, bokhoni bo phahameng ba ho sila.

4. Ha ho tšilafalo ea lerōle.

5. Alloy forged handle, e thata ebile e tšoarella.

Melemo ea Rōna

1. Re setsebi sa carbide burr moetsi ho tloha 1992. Ka lilemo tse 30 tsa lisebelisoa tsa abrasive, 'me nako ea ho sila ea li-workpieces ka sebele e telele ho feta ea ba bang.

2. Sehlahisoa se seng le se seng se tla lekoa pele se tloha fekthering ho netefatsa hore boleng ba sehlahisoa bo lokile.

3. Re na le thepa e kholo ea mehlala e tloaelehileng e tloaelehileng 'me re ka hlophisa ho fana ka matsatsi a supileng.

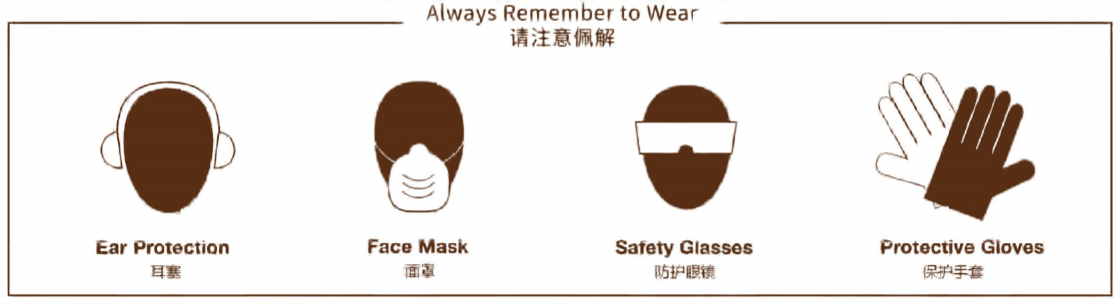

Tsepamisa maikutlo

1. Ha sesebelisoa se sa tsoa kenngoa, se tlameha ho lekoa hore na sesebelisoa sea qhoma.Haeba e etsa joalo, e ke ke ea sebetsoa ka kotloloho.E ka sebelisoa feela ka mor'a hore e lokisoe hore e se ke ea qhoma.Ho seng joalo, lisebelisoa li tla fela ka potlako 'me lintho tse betliloeng li ke ke tsa e-ba boreleli.Mokhoa oa ho fetola: tlanya ka bonolo sesebelisoa sa sesebelisoa se potolohang ka lebelo le phahameng ka wrench e nyenyane e fetolang collet ho fihlela sesebelisoa se tsitsitse.Ho thibetsoe ka thata ho kokota mochine oa elektronike.Mokhoa oa ho lokisa ke ho lokolla collet le ho fetola sesebelisoa ho angle kapa ho atolosa le ho hula hanyenyane.

2. Etsa bonnete ba hore o hula metsi bakeng sa ho tsidifatsoa (joaloka sesebelisoa se rothang sepetlele) e le hore a tle a aparoe le ho hlakoloa haufinyane.Bakeng sa ho phunya ho omileng, daemane e hloohong ea sesebelisoa e tla ba graphitized ka lebaka la ho chesa haholo.

3. Nakong ea ho phunya, leka ho qoba ho sisinyeha, hobane ho sisinyeha ho tla baka tšenyo ea sebaka ho sesebelisoa le ho potlakisa tšenyo ea sesebelisoa kaofela.

4. Fetola holimo kamoo ho ka khonehang.Ka kakaretso, lebelo la mela ha lea lokela ho ba tlase ho limithara tse 10-20 motsotsoana.

5. Tobetsa ka bonolo.Lisebelisoa tsa daemane li sebetsa li-workpieces ka ho sila.Matla a feteletseng a etsa hore ho be thata ho felisa ho sila le lisebelisoa ho bonolo ho senyeha.

6. Ho eketsa metsi ho molamu oa ho sila oa daemane ho ka ntlafatsa ho hanyetsa ho apara le ho hlaba ha hlooho ea ho sila, ebe joale ho ntlafatsa bophelo ba tšebeletso.