Cylindrical-A Diamond e Sila Lisebelisoa tsa ho Seha Hlooho

Setšoantšo sa Sehlahisoa

Lintlha tsa Motheo tsa Sehlahisoa

Lebitso la Sehlahisoa: Hlooho ea ho Sila ea Diamond

Mohlala oa Sehlahisoa: Cylindrical-A

Boitsebiso ba Hlooho: Diamond

Kopo ea Sehlahisoa: 1. Karolo ea hlobo e fatše 'me e bentšitsoe.2 Ho roala le ho rema tšepe e sa hloekang.3 Ts'ebetso ea ho lokisa lesoba la shoa.4 Ho betla le ho sila likarolo tsa tšepe.

Bophara ba hlooho: 6mm/8mm/10mm/13mm/15mm/18mm/20mm

Bolelele ba Hlooho: 30mm

Bolelele ba Shank: 30mm

Molemo: 1. Thepa ea daemane, ha ho bonolo ho e holofatsa.2. Lerōle le fokolang, tšireletso e eketsehileng ea tikoloho.3. Tšepe e phahameng ea manganese, matrix e teteaneng.4. Molamu o matlafatsang o etselitsoe ho lelefatsa bophelo ba tšebeletso.

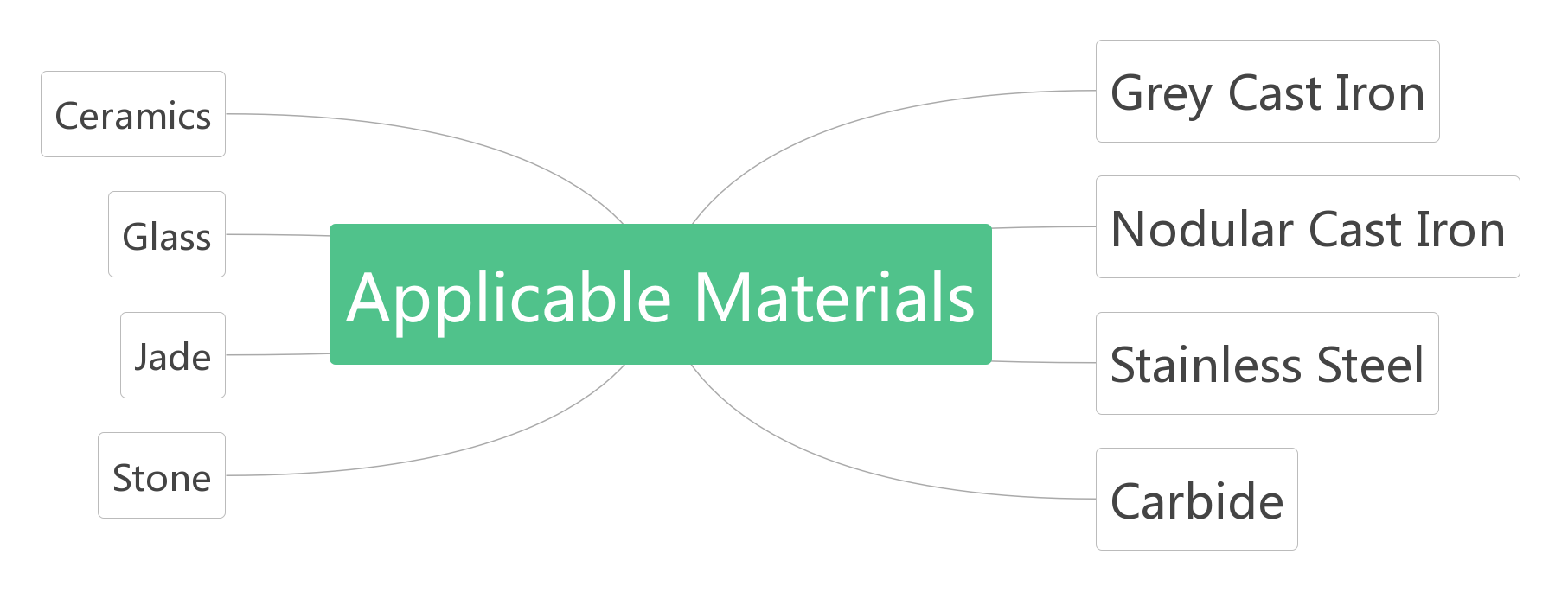

Lisebelisoa tse Tšebelisoang

Kopo

1. Ho sebetsa le ho lokisoa ha hlobo.

2. Ho ngola ka majoe, ho betla, ho seha mela, ho sila, ho fata.

3. Ho betla likhalase.

4. Ho hloekisa li-casting, forging, welding edges, burrs, welds.

5. Ts'ebetso ea ho sila leino.

6. Chamfering le groove processing ea likarolo tse sa tšoaneng tsa mechine, ho hloekisa liphaephe, ho qeta sekoti se ka hare sa likarolo tsa mechine.

7. Phetoho ea mosebetsi oa geometry.

8. Setlankana sa tleliniki ea meno.

Litekanyo tsa Sehlahisoa

| Mohlala | Diameter | Kakaretso ea Bolelele | Bolelele ba ho Sebetsa | Bolelele ba Shank | Shank Diameter |

| Cylindrical 6*6 | 6mm | 60 limilimithara | 30 limilimithara | 30 limilimithara | 6mm |

| Cylindrical 6*8 | 8mm | 60 limilimithara | 30 limilimithara | 30 limilimithara | 6mm |

| Cylindrical 6*10 | 10 limilimithara | 60 limilimithara | 30 limilimithara | 30 limilimithara | 6mm |

| Cylindrical 6*13 | 13 limilimithara | 60 limilimithara | 30 limilimithara | 30 limilimithara | 6mm |

| Cylindrical 6*15 | 15 limilimithara | 60 limilimithara | 30 limilimithara | 30 limilimithara | 6mm |

| Cylindrical 6*18 | 18mm | 60 limilimithara | 30 limilimithara | 30 limilimithara | 6mm |

| Cylindrical 6*20 | 20 limilimithara | 60 limilimithara | 30 limilimithara | 30 limilimithara | 6mm |

Scenario e sebetsang

Papiso ea Sehlahisoa

Hlooho e tsikinyang

● Bophelo bo bolelele ba tšebeletso, bo tšoarellang ho feta lihlooho tse tloaelehileng tsa ho sila

● Lerōle le fokolang, le baballang tikoloho

● Ho sila ka bohale le bokhoni bo phahameng

● tšepe e phahameng ea manganese, matrix e teteaneng

Hlooho e silang ya setso

● Bophelo bo bokhutšoanyane ba tšebeletso, khatello ea kelello e sa lekaneng e tla hlahisa deformation

● Lerōle le leholo, ’me le baka kotsi ’meleng oa motho

● Bophelo bo bokhutšoanyane ba tšebeletso, ho nkela sebaka ka letsoho ho ja nako ebile ho boima

● Mohatla o tloaelehileng oa thepa, o robeha habonolo, o fokola

Melemo ea RuiXin

1. Re setsebi sa carbide burr moetsi ho tloha 1992. Ka lilemo tse 30 tsa litsebi tsa ho itšeha, 'me nako ea ho sila ea li-workpieces ka sebele e telele ho feta ea ba bang.

2. Boitsebiso ba rona ke 100% diamond.

3. Feme e 'ngoe e sebelisitse thepa e nchafalitsoeng ho etsa theko e tlase ea boleng bo tlase.

4. Likhoutu tse ling tse tloaelehileng li na le thepa 'me li ka romelloa ka hare ho matsatsi a 7!

Melemo ea ho Sila Litaemane

1. Katleho ea mosebetsi: katleho ea mosebetsi e eketseha ka 35%.Bakeng sa lisebelisoa tse thata tse phahameng le li-castings tse kenyelletsoeng lehlabathe, katleho ea mosebetsi e eketseha ka nako ea 5-10.

2. Molemo: bakeng sa lisebelisoa tse thata tse phahameng le li-castings tse kenyelletsoeng lehlabathe, sengoathoana se le seng se lekana le likotoana tse tloaelehileng tsa 100-300 tsa ho sila.

3. Tšireletso ea tikoloho: abrasive ha e na sebabole, ha e oe, 'me tšilafalo ea lerōle le litšila li batla li le zero.

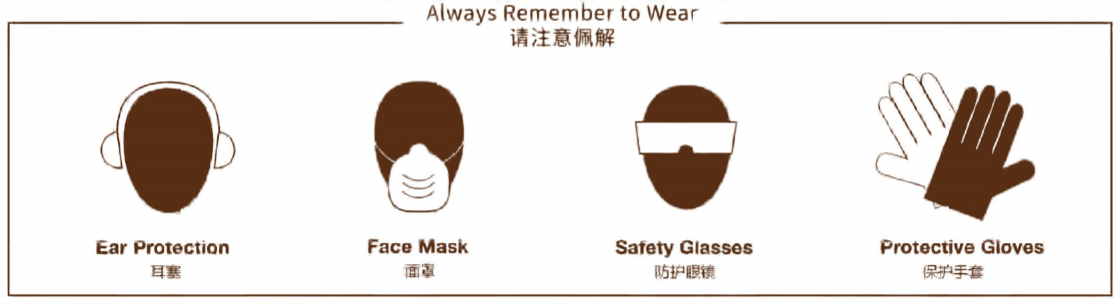

4. Tšireletseho: matrix a tšepe a matla a phahameng a amoheloa, 'me ha ho na kotsi e ka bang teng ea tšireletso e bakoang ke lithōle tse fofang ka ntle.