Khetho le ts'ebeliso ea thepa le mohlala oa mochini oa ho sila o itšetlehile ka thepa ea ho sebetsa le morero oa ho sebetsa.

Ka tlase ho na le limaraka tse tloaelehileng tsa li-milling cutter le litlhahiso tsa khetho:

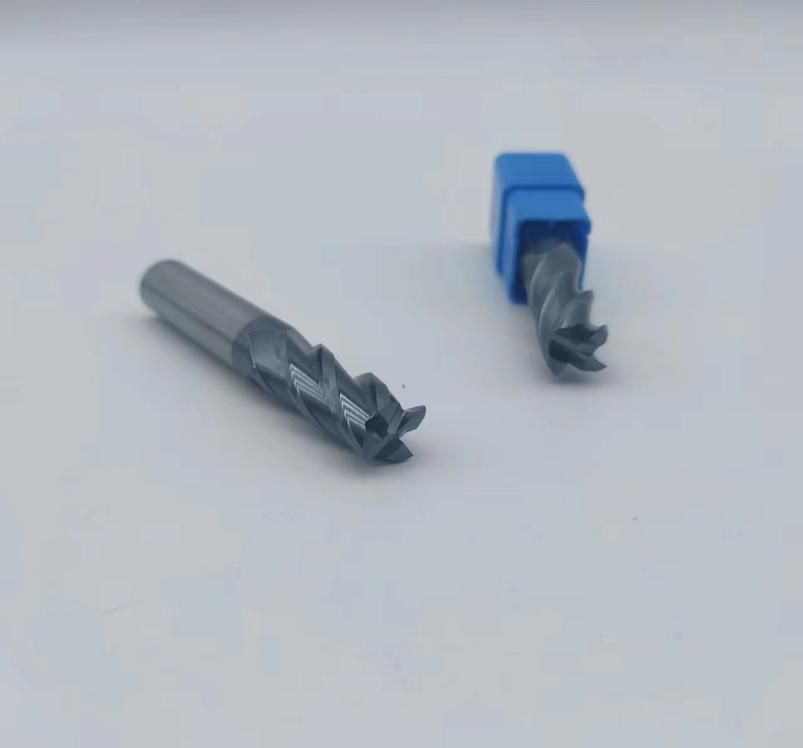

1. High-speed steel (HSS) ho roala sekontiri: e loketseng ho sebetsana le lisebelisoa tse ling tse thata, tse kang tšepe, tšepe e entsoeng ka tšepe, tšepe e sa hloekang, joalo-joalo.

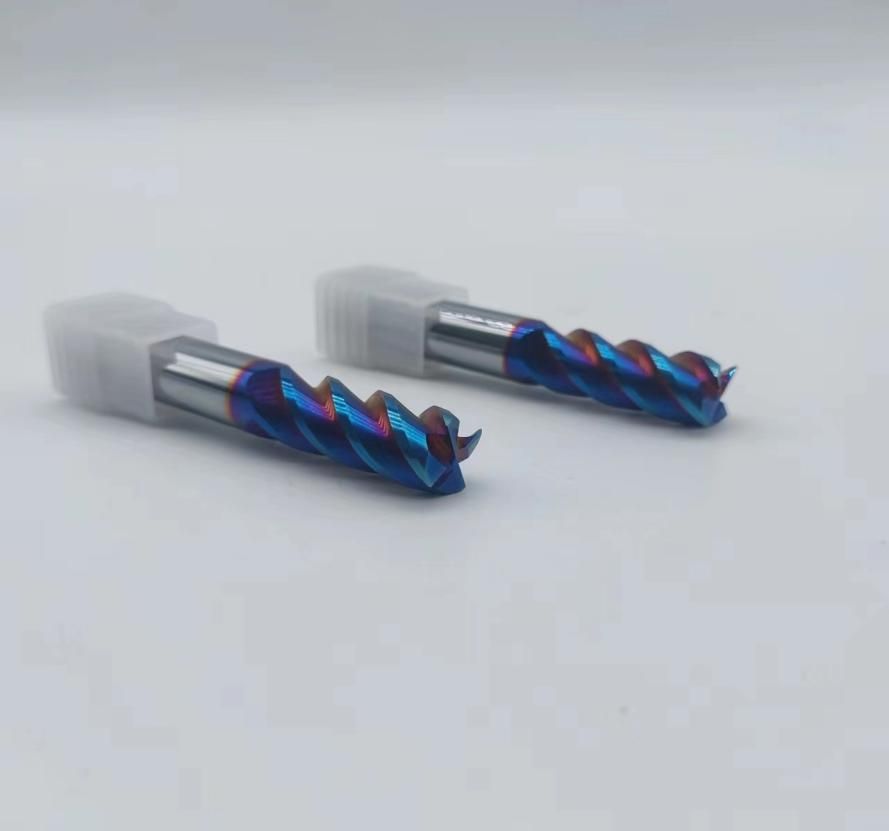

2.Tungsten carbide (WC) mochini oa ho sila: o loketse ho sebetsana le lisebelisoa tse thata tse phahameng, tse kang titanium alloy, high hardness alloy steel, joalo-joalo Ka lebaka la boima ba eona bo phahameng, ho kgothaletswa bakeng sa ho pholile ha metsi.

3.PCD milling cutter (polycrystalline diamond): e loketse ho sebetsana le lisebelisoa tse thata haholo, tse kang lisebelisoa tsa refractory, li-ceramics, khalase, joalo-joalo Ka lebaka la ho senyeha ha mocheso o futsanehileng, e tlameha ho sebelisoa tlas'a pholileng ea metsi.Ha u khetha mofuta oa seha sehalo, o lokela ho nahanoa ho latela boima, boleng ba bokaholimo le bophahamo ba molumo oa thepa e sebetsitsoeng.Ka kakaretso, ho ka sebelisoa meno a mangata a sehaho sa ho sila ho ntlafatsa boreleli holim'a metsi, athe meno a fokolang a ka sebelisoa ho eketsa lebelo la ho sebetsa, empa tlhokomelo e lokela ho nkoa ho qoba ho hlahisa mocheso o feteletseng nakong ea tšebeliso.Ho phaella moo, tšebeliso ea li-milling cutters tse nyenyane haholo kapa tse kholo haholo li lokela ho qojoa, e le hore li se ke tsa baka tšenyo ho li-milling cutters tse nyenyane haholo, 'me li-milling cutters tse kholo haholo li tla baka ts'ebetso e sa tsitsang le ho senya litšila.

Bophelo ba ts'ebeletso ea seha sehahi se ipapisitse le lintlha tse ngata, joalo ka thepa, geometry, lisebelisoa tsa ho sebetsa, matla a ho itšeha, lebelo la ho itšeha le mokhoa oa ho pholisa oa seha sehahi.Ka kakaretso, li-cutters tsa milling li tla ba le mokhathala le mokhathala nakong ea ho sebetsa, ho etsa hore li lahleheloe ke bohale le ho nepahala ha tsona, e leng se tla fella ka ho fokotseha ha boleng ba sehlahisoa le ho fokotsa bokhoni ba ho itšeha.

Bakeng sa ho lelefatsa bophelo ba ts'ebeletso ea mochini oa ho sila, lintlha tse latelang li lokela ho eloa hloko:

1.Khetha lisebelisoa tse nepahetseng tsa ho sila le geometry, 'me u khethe ho ea ka boima, lebelo la ho itšeha le litlhoko tsa bophelo ba lisebelisoa tsa thepa e entsoeng.

2.Ho beha ka mokhoa o utloahalang li-parameter tsa ts'ebetso, tse kang lebelo la ho itšeha, lebelo la ho fepa le ho itšeha botebo, joalo-joalo, 'me u qobe ho sebelisa lebelo le phahameng ka ho fetisisa la ho itšeha le lebelo la ho fepa ho qoba ho apara ho feteletseng.

3. Boloka li-cutters tsa ho sila li pholile li bile li tlotsitse, sebelisa lipholisa le mafura a loketseng ho qoba mocheso o feteletseng le ho khathala.

4. Hloekisa khafetsa 'me u hlahlobe li-milling cutters, qoba mokhoa o mobe oa ho bokella li-chips le li-deposit, 'me kamehla u hlahlobe le ho kenya li-cutters tse tsofetseng haholo.

5. Boloka le ho sireletsa li-griller hore li se ke tsa senyeha ke mechine, lik'hemik'hale kapa tse senyang, tse kang ho sebelisa mabokose a porofeshenale kapa li-jigs, 'me u qobe ho pepesehela likhase tse kotsi kapa mahlaseli a letsatsi.

Nako ea poso: Mar-13-2023