Wood Angle Grinding Wheel Shape A-Abrasive Tool

Setšoantšo sa Sehlahisoa

Lintlha tsa Motheo tsa Sehlahisoa

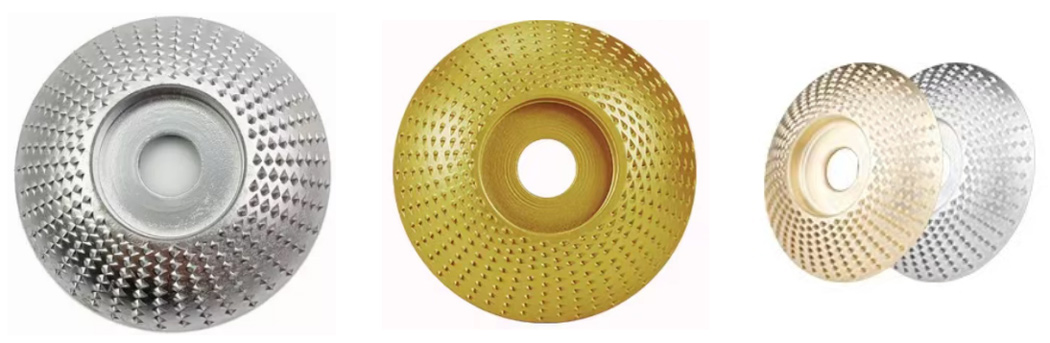

Lebitso la Sehlahisoa: Wood Angle Grinding Disc

Mohlala oa Sehlahisoa: GT-A

Boitsebiso ba Sehlahisoa: 45 # Tšepe

Ka hare bophara: 16mm / 22.2mm

Ka ntle bophara: 85mm/100mm/115mm/125mm

Molemo: 1. Alloy forging, phekolo ea ho tima mocheso o phahameng, boima bo phahameng, ho theha ho kopantsoeng, boima bo lekanang le ho se sisinyehe.2. Meno a bohale ebile a thata, a na le bophelo bo bolelele ba tšebeletso.3. Moqapi o tebileng oa groove ka morao, ka potlako ho theosa le letsoapo le lebelo le phahameng.4. E matla le e sebelisoang haholo, e loketseng bakeng sa ho sila le ho rema lifate tsohle tse bonolo le tse thata.

Kopo ea Sehlahisoa: E loketse ho sila terei ea tee, ho bopa lehong, ho betla metso, ho phunya lehong, ho sila ka matsoho, ho sila lejoe la mokoetla, joalo-joalo.

Mmala: Botsho, Boputsoa, Pinki, Bokhubelu, Khauta, Silevera, joalo-joalo.

Lisebelisoa tse Tšebelisoang

Terei ea tee

Ho betla ka metso

Mesebetsi ea matsoho

Lehong

Litekanyo tsa Sehlahisoa

| Modle | Dia ka hare | Dia e Ntle |

| GT-A1 | 16/22.2mm | 85 limilimithara |

| GT-A2 | 16/22.2mm | 100mm |

| GT-A3 | 16/22.2mm | 115 limilimithara |

| GT-A4 | 16/22.2mm | 125 limilimithara |

Melemo ea Rōna

1. Re setsebi sa carbide burr moetsi ho tloha 1992. Ka lilemo tse 30 tsa litsebi tsa ho itšeha, 'me nako ea ho sila ea li-workpieces ka sebele e telele ho feta ea ba bang.

2. Boitsebiso ba rona ke 100% 45 # tšepe.

3. Feme e 'ngoe e sebelisitse thepa e tsosolositsoeng ho etsa theko e tlase ea boleng bo tlase.

4. Likhoutu tse ling tse tloaelehileng li na le thepa 'me li ka romelloa ka hare ho matsatsi a 7!

Scenario e sebetsang

Molemo oa Sehlahisoa

1. Alloy forging, sehlahisoa se tingoa ka mocheso o phahameng, ka boima bo phahameng, sebopeho se kopantsoeng, boima bo lekanang 'me ha se sisinyehe ha se sebelisoa.

2. Mokhoa oa leino o amohela moralo oa leino o khelohileng, o bohale le o thata, o benngoeng ka potlako, ntle le ho putlama ha bohale le bophelo bo bolelele ba tšebeletso.Moralo oa conical oa moeli oa thipa o loketse ho lahla lithōle nakong ea ho sila le ho netefatsa ho bata ha sebaka sa ho sila.

3. Moqapi o tebileng oa groove ka morao, ka potlako ho theosa le letsoapo le lebelo le phahameng.

4. Mefuta e matla, e sebelisoang haholo le e sa tšoaneng, e loketseng ho sila le ho roala mapolanka 'ohle a bonolo le a thata le lisebelisoa tse se nang tšepe.

Tlhokomeliso

1. Ha u qala lebili la ho sila, ho sila ho ka etsoa feela ka mor'a hore lebelo le tsitse ka metsotsoana e 40 ~ 60.Ha u sila sesebelisoa, ema ka lehlakoreng la lebili le silang 'me u se ke ua shebana le lebili le silang ka ho toba, e le ho thibela lebili le silang hore le se ke la robeha le ho fofa le ho ntša batho kotsi.

2. Lebiling le le leng la ho sila, batho ba babeli ha ba lumelloe ho le sebelisa ka nako e le 'ngoe, ho sa bue letho ka ho sila ka lehlakoreng la lebili la ho sila.Nakong ea ho sila, opereishene o lokela ho ema ka lehlakoreng la grinder ea angle, eseng ka pele ho grinder, e le ho thibela lebili le silang hore le se ke la phatloha le likotsi.Ka nako e ts'oanang, ha e lumelloe ho sebetsa ka liatlana.Ho thibetsoe ka thata ho sebetsa ka har'a qubu le ho tšeha le ho loana nakong ea ho sila.

3. Boemo bo emeng nakong ea ho sila bo tla theha angle e kenyelletsoeng ka grinder ea angle, 'me khatello ea ho kopana e tla tšoana.Ho thibetsoe ka thata ho otla lebili le silang ho qoba ho arohana.Lebili la ho sila le lekanyelitsoe ho lisebelisoa tsa ho sila, lisebelisoa tse boima kapa lipoleiti tse tšesaane tsa tšepe, lisebelisoa tse bonolo (aluminium, koporo, joalo-joalo) le lihlahisoa tsa lehong.

4. Ha o sila, opereishene o lokela ho ema ka lehlakoreng kapa lehlakoreng le sekametseng la lebili la ho sila, eseng ka pele ho lebili la ho sila, 'me sesebelisoa se lokela ho ba holimo hanyenyane ho feta bohareng ba lebili la ho sila.U se ke ua sebelisa matla a mangata ho thibela kotsi matsohong.

5. Lebili la ho sila le ke ke la pepesetsoa metsing 'me le tla bolokoa le omme khafetsa ho thibela tahlehelo ea tekanyo le kotsi ka mor'a metsi a metsi.

6. Ha e lumelloe ho sila lintho tse kholo le tse telele holim'a grinder ea angle ho thibela lebili la ho sila hore le se ke la fofa le ho ntša batho kotsi.

7. Ha e lumelloe ho sila workpiece ka letsoho ho thibela ho oela le ho pshatla lebili le sila ka sekoahelo se sireletsang.